PEEK products features

Excellent high temperature performance: PEEK material has a wide range of temperature, can withstand temperatures up to 260 ℃ for a long time, and even up to 310 ℃ for a short period of time. This makes PEEK machined products have excellent stability in high temperature environments, suitable for a variety of high-temperature work environment.

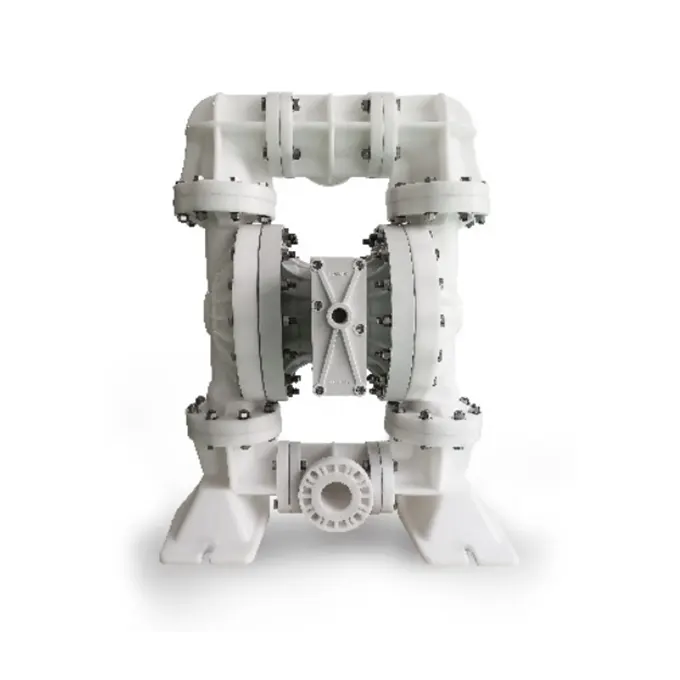

Excellent corrosion resistance: PEEK materials have good corrosion resistance to most organic solvents, acids, alkalis and other chemicals. Therefore, PEEK machined products in the chemical industry, such as chemical equipment, piping, valves and other parts of the manufacturing has a wide range of applications.

Excellent mechanical properties: PEEK material has high strength, high modulus, high toughness and wear resistance and other excellent mechanical properties. This makes PEEK machined products in the manufacture of high-quality engineering parts are widely used, such as automotive engine parts, transmission system parts, brake system parts and so on.

Good processing performance: PEEK material is easy to process, can be injection molding, extrusion, machining and other molding processes. This makes the manufacturing process of PEEK machined products more flexible and efficient, and can meet the customized needs of different customers.

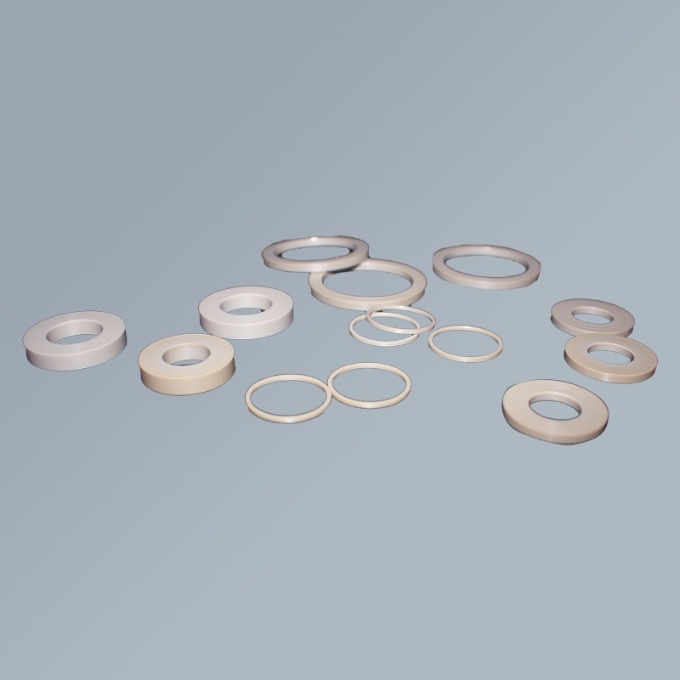

Uses

There is a wide range of PEEK machined products, including PEEK thrust washers, PEEK automatic transmission check balls, PEEK sealing rings, etc., each of which is designed and manufactured according to their specific application scenarios and needs. These products not only have excellent performance, but also have flexible processing to meet the customized needs of different customers. They have become an indispensable and important material in modern industry, providing more possibilities for the development of various industries.

| Properties | Unit | Idicator |

| Tensile Strength | Mpa | 》15 |

| Elongation at Break | % | 》150 |

| Apparent Density | g/cm² | 2.1-2.3 |