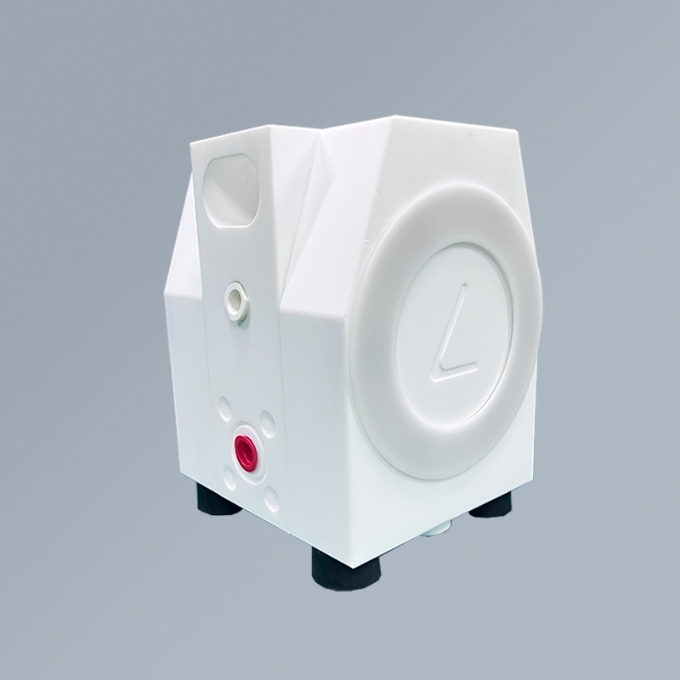

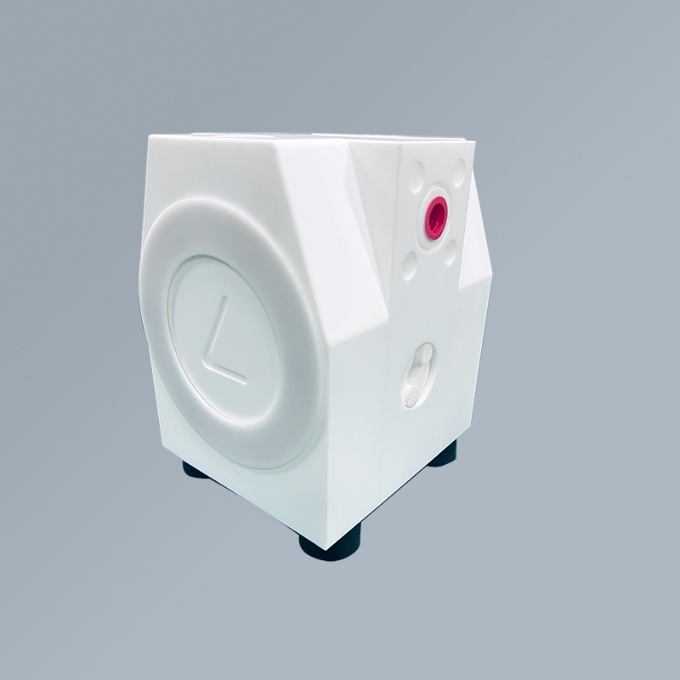

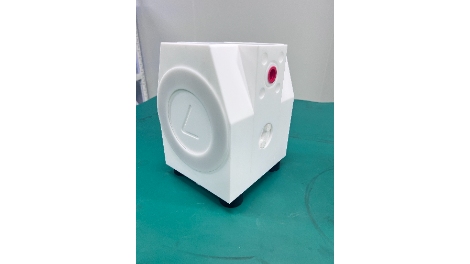

High-purity Chemical Manufacture: The liquade EX-Series pump

To ensure in-spec production of high-purity chemicals (which can alsobe toxic or dangerous to handle). manufacturers are finding thatsolid-body plastic air-operated double-diaphragm (EX) pumps are the perfect choice,offering the added benefits of chemical resistant mate-rials,optimized product containment,elimination of product cross-con-tamination and improved environmental protection.

Specifically, Liquade E-Series EX Pumps shine in high-purity chemi-cal-manufacturing applications for a variety of reasons.

|

|

|

|

|

|

EX-Series pump available in three sizes:

EX150(1/2") / EX200(1") / EX400(1.5”)

| FEATURE | BENEFIT | VALUE |

| Solid-Block Design, Machine Engineered |

●High static weight reduces pump-bodyvibration ●No exposed metal parts |

●Can be used in corrosive atmospheres ● Improved safety ●Easier maintenance |

| PE or PTFE Construction |

●Excellent chemical abrasion and good corrosion resistance of polyethylene (PE) ●Universal chemical corrosion resistance of PTFE |

●Improved durability ●Longer lasting ● Less maintenance |

| Consistent Interior Housing Design |

● Good self-priming values ● Accommodates ball or cylinder valves of varying materials |

● Gentle fluid flow ● Compatible with a wide range of chemical types ● Full containment |

| Pulsation Damper (optional) |

●Self-regulating ●No exposed metal parts ●Attached directly to pump with no need for additional piping ●Flanged versions available |

● Easy to install ● Maintenance-free ● Delivers virtually uniform flow ● Protects pipework |

| Internal Drain System (optional) |

● Installed in side housings ● Allows draining with no need to disconnectfrom piping ● Reduces amount of cleaning agent and solvent needed ● Product recovery of precious liquids |

●Valves can be manually or pneumatically operated ●Reduces maintenance needs e Virtually eliminates residue in the pump Reduces environmental pollution |

LIQUADE Advantage

MATERIALS OF CONSTRUCTION

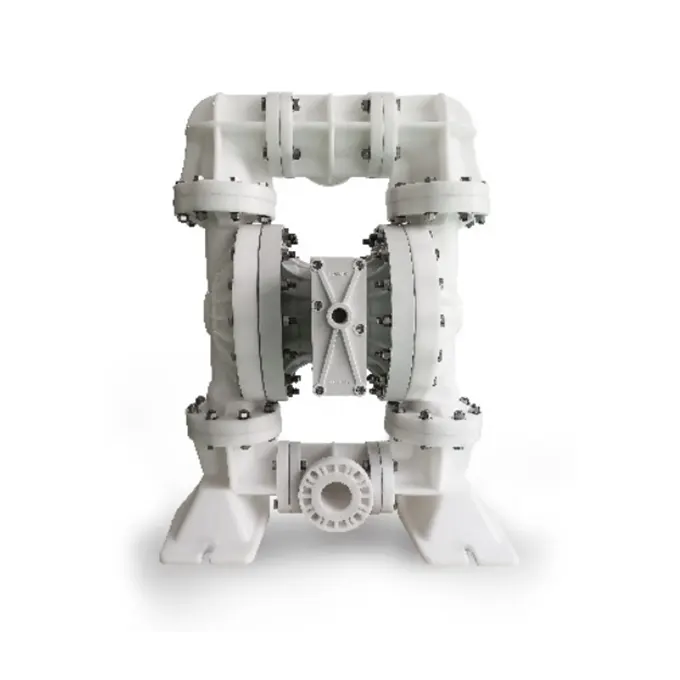

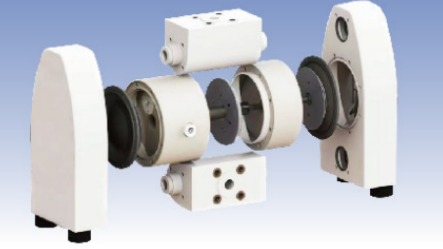

All Ex-Series pumps housings and components are constructed of polyethylene (PE) or polytetrafluoroethylene (PTFE) in a solid-block design.PE offers excellent abrasion resistance higher than steel and PTFE an universal chemical resistance.These are prime considerations when handling high-purity, aggressive,corrosive,toxic or hazardous media.

INTEGRAL DIAPHRAGMS

Ex seires PTFE diaphragms feature a metal core that is built into the center of the diaphragm material, meaning that no diaphragm discs are required, which eliminates notorious leak or product-nesting points. The diaphragm's surface is also smooth, which contributes to flow uniformity.

AIR CONTROL SYSTEM

LIQUADE EX series enables to achieve superior efficiency in flow rate and air consumption, which translates into lower energy costs. The highly accurate reversal of the main piston, which has only two moving parts, results in low noise levels, less required maintenance,and stall-free operation.

UNIQUE TENSION RING

Ex-Series pumps feature a stainless-steel tension ring that provides consistent high-torque compression around the entire diameter of the ring and the pump housing, ensuring a leak-free seal.

BARRIER-CHAMBER SYSTEM/DRAINING SYSTEM

The individual diaphragm is replaced by two diaphragms arranged in tandem with a barrier chamber of conductive PE between them and filled with a non-conductive liquid. Any change in the conductivity of the barrier liquid is detected by sensors andsignaled to a controller, which triggers an alarm or halts pump operation.

The Internal Drain System consists of a bypass system in the side housings that can be activated either through hand-operated valves or pneumatically, which allows the pump and piping to be drained without having to be disconnected. This capability also reduces the amount of cleaning agent and solvent that is needed, which also greatly reduces environmental pollution. All of these capabilities make possible the recovery of high value liquids.

Technical Data

MACHINED FOR PRECISION

The pump's solid-body PE block construction increases its strength and operational life cycle while eliminating many maintenance concerns.

The pump's body and other components are CNC-machined rather than, as is the case with many competitive models, injection-molded.

The CNC based design enables tight tolerances,lower risk of leakage,and greater stability and durability. Thesolid block's

|

|

|

LIQUADE EXH-Series

ACost-Effective Plastic EXH Pump with Liquade Quality

Air-operated double-diaphragm pump

available in two sizes:

EXH200(1”)and EXH400(1.5”)

- o Reliable LIQUADE solid-design construction

- o Manifolds as separate housing parts

- o High level of pump safety due to innovative ring-tightening structure

- o Wetted housing materials PE ,also conductive

- o Diaphragms and ballvalves made of EPDM and PTFE

- o Maintenance and lubrication-free EX air control system

- o Good suction head,self-priming,and dry-run capability

- o No drives,no rotating parts, no shaft seals within fluid

- o Stroke counting and diaphragm monitoring available as accessories

- o Different connection options available to match to existing installations

Spare Part Kits

Spare part kits Sfor pumps of the EXH series arecompiled for single-shift operation (8 hours perday). These kits ensure that the correct replace-ment parts are always available in the required quantities.This helps to avoid production

stoppages and ensures that the LIQUADE pumps are always readyfor action. Besides, it is cheap-er to buy spare parts as a kit than individually. The standard configuration of the suction and discharge ports are according to the illustration: Discharge port to the top, suction port forward.

EXH Series

Pump with internal pressure booster

The two sizes of the EXH series feature anextremely rugged housing that is suitable for higher discharge pressures.

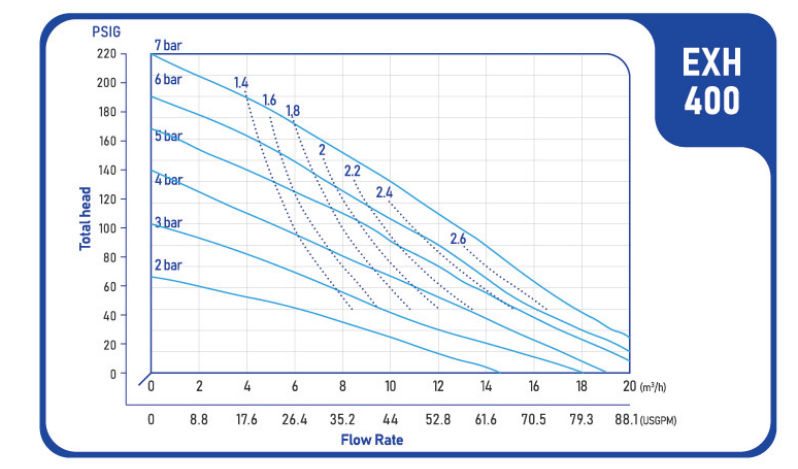

Basically, the EXH series can be used for every application under heavy load conditions.The EXH series pump is equipped with an internal supercharger, and the driving pressure in the internal supercharging stage exceeds 2:1. The maximum driving pressure is 8 bar (116 psig),which allows EXH to generate up to 16 bar (232 psig) of discharge pressure.

Features & Benefits

- o Air-operated double-diaphragm pumps designed for a discharge pressure up to 16 bar (218 psig)

- o Maximum capacities of 4,10 and 20 m /h (17,44 and 87 gpm) forEXH pumps resp. 4 and 8 m/h (17 and 35 gpm)

- o High pump safety due to innovative ring-tightening structure

- o Automatic pressure/volume adjustment for filterpress feeding

- o No control or safety elements required for

- o Dry running

- o Over pressure

- o Speed control

- o No drives, no rotating parts, no shaft seals

- o Running dry capability

Other Special Features

LIQUADE high-pressure diaphragm pumps are equipped with specially developed heavy-duty diaphragms with integrated metal core for a long service life.The service life is in lended once more by a supporting disc on the air side. The diaphragms are made of either EPDM or PTFE/EPDM-compound.

The metal-free. pneumatically pilot-operated EX air control system ensures accurate reversal of the main piston and is characterized by low noise levels. Only two moving parts ensure that there is absolutely no dead center. It does not require main-tenance, operates without any lubrication whatsoever and is made up of no more than four different parts.The complete cartridge can be replaced easily. The patented EX is a precision control system and therefore requires clean, oil-free compressed air to ensure its optimal function.

The easy replaceable ball valves and ball retainers have been specially designed to make them particularly suitable for high pres-sures. They are insensitive to solids. The ball valves are available in the materials EPDM, and PTFE.

Optional Equipment

Stroke counting (code C): A sensor is installed in the center block to count the strokes. The diaphragm movement is scanned without contact by this sensor. The issued sensor pulses can be output to existing detectors orto a stroke count-er(can also be supplied. When the preset value is reached, the stroke counter outputs a signal which can then be processed further, for instance in order to shut down the pump via a solenoid valve (available also in a pn-eumatic version). Diaphragm monitoring (code D): A sensor installed in the pump muffler detects all liquids which occur because of diaphragm damage. Pressure booster (code BO): The booster for the EXH series is available in two sizes.

Pump and booster will be shipped as one unit.

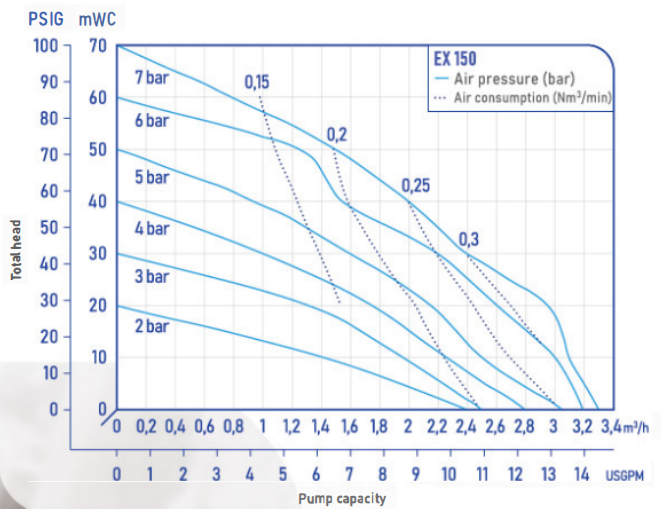

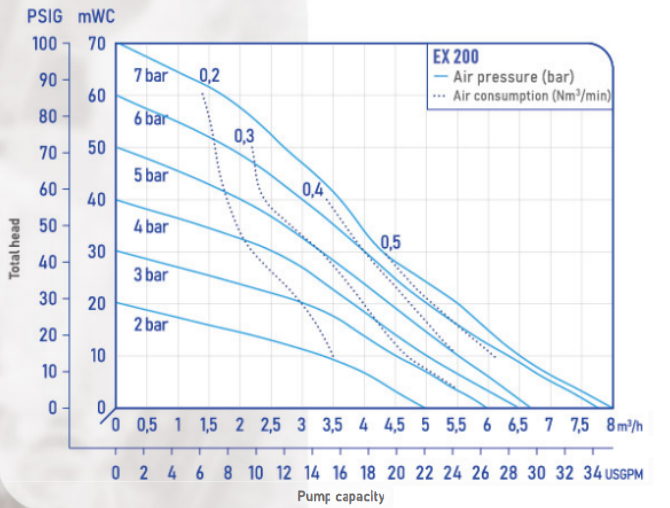

Performance Range

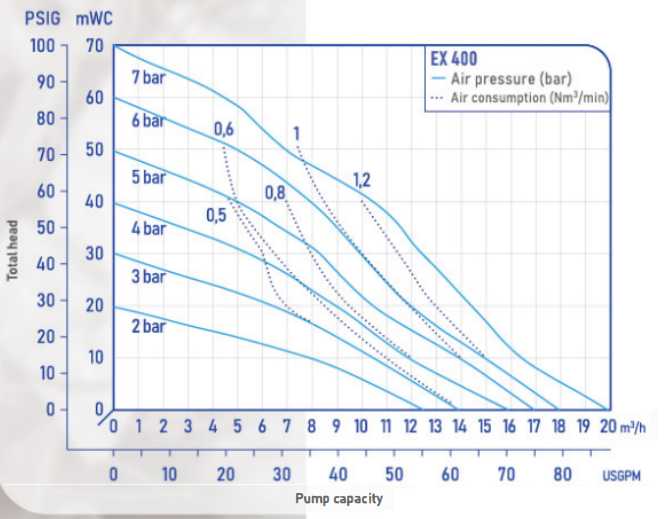

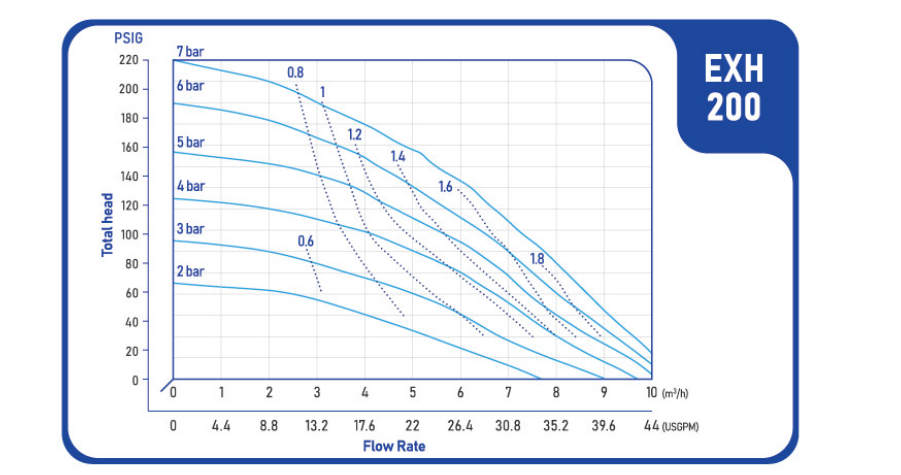

The following data refer to water at 20C (68°F) (referring DIN EN ISO 9906).

The blue lines state the air consumption in Nm2/3/min.

The characteristics of theEXH series with internal pressure booster are displayed on the left side. The maximum total head at an air supply pressure of 7 bar (100 psig) is 150 mWc.

The upper two curves on the right side refer to the EXH series, which operates without internal pressure booster. Their maximum total head depends on the selected drive air pressure. In these charts a maximum air pressure of 7 bar (100 psig) is assumed. The lower curve is an example of the performance range of a of aEXH 200 with an external booster (special equipment code B02).By using of another booster model a changed performance can be expected.

|

|

EX-Series pump available in three sizes: EX150 (1/2″) /EX 200(7″) / EX400 (1.5″)

| FEATURE | BENEFIT | VALUE |

| Solid-Block Design, Machine Engineered |

· High static weight reduces pump-body vibration · No exposed metal parts |

· Can be used in corrosive atmospheres · Improved safety · Easier maintenance |

| PE or PTFE Construction |

· Excellent chemical abrasion and good corrosion resistance of polyethylene (PE) · Universal chemical corrosion resistance of PTFE |

· Improved durability · Longer lasting · Less maintenance |

| Consistent Interior Housing Design |

· Good self-priming values · Accommodates ball or cylinder valves of varying materials |

·Gentle fluid flow · Compatible with a wide range of chemical types · Full containment |

| Pulsation Damper (optional) |

· Self-regulating · No exposed metal parts · Attached directly to pump with no need for additional piping · Flanged versions available |

· Easy to install · Maintenance-free · Delivers virtually uniform flow ·Protects pipework |

| Internal Drain System (optional) |

· Installed in side housings · Allows draining with no need to disconnect from piping · Reduces amount of cleaning agent and solvent needed · Product recovery of precious liquids |

· Valves can be manually or pneumatically operated · Reduces maintenance needs · Virtually eliminates residue in the pump · Reduces environmental pollution |