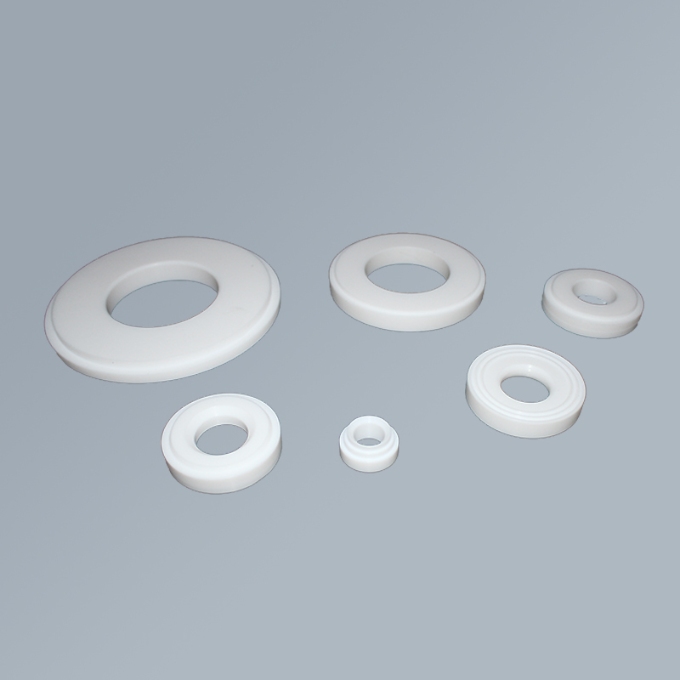

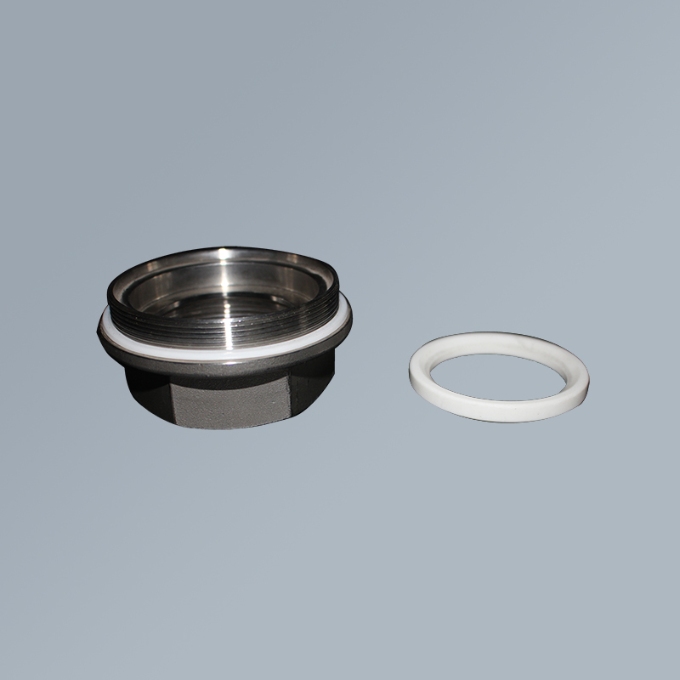

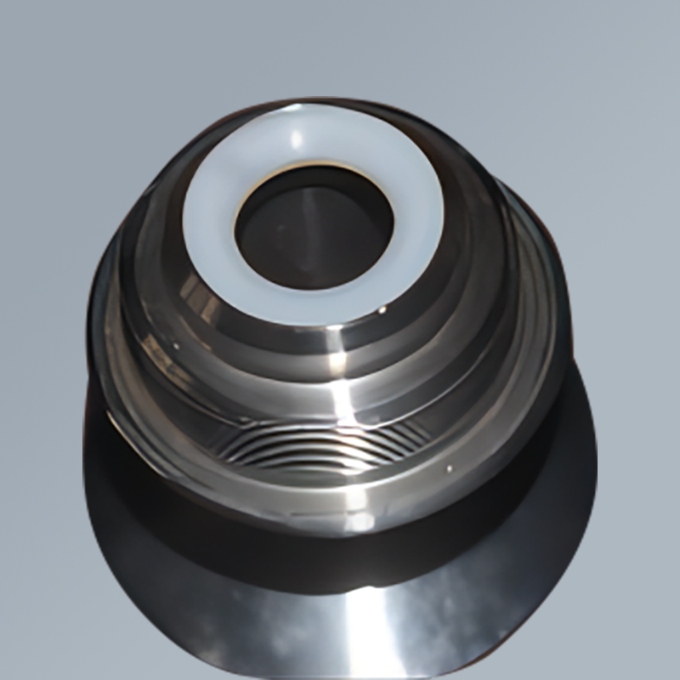

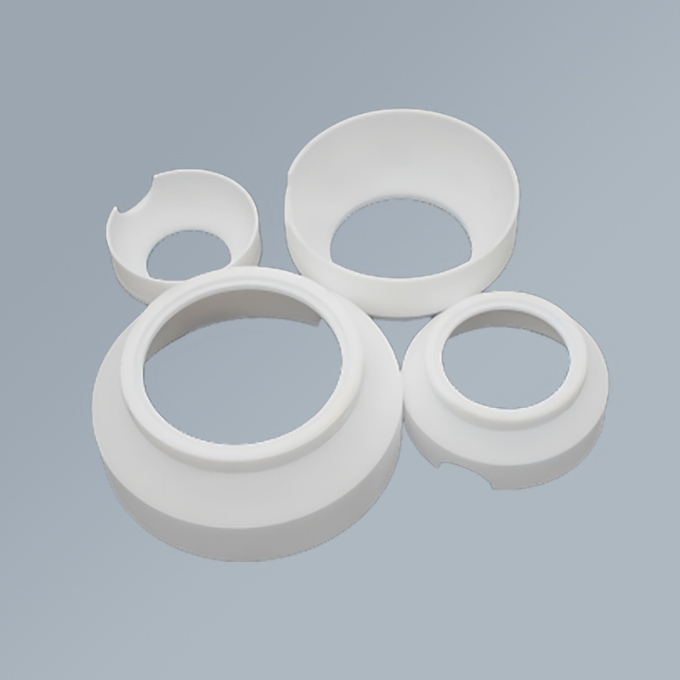

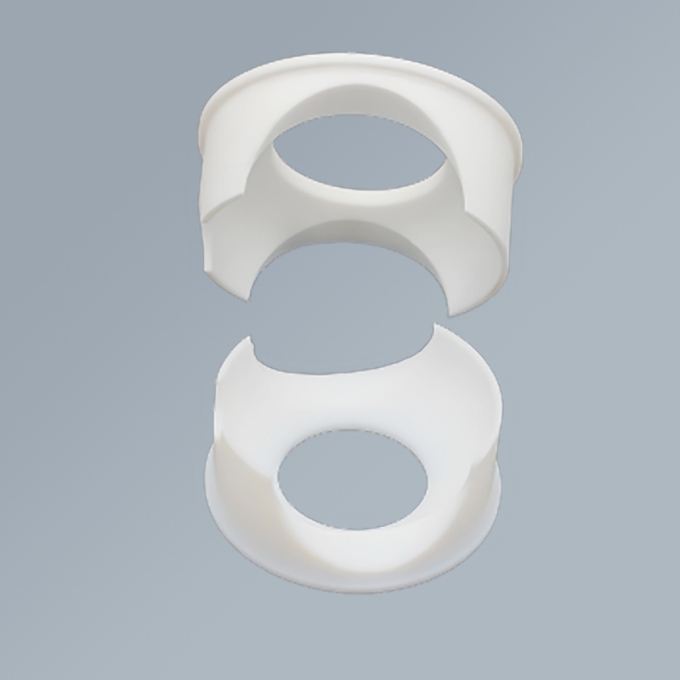

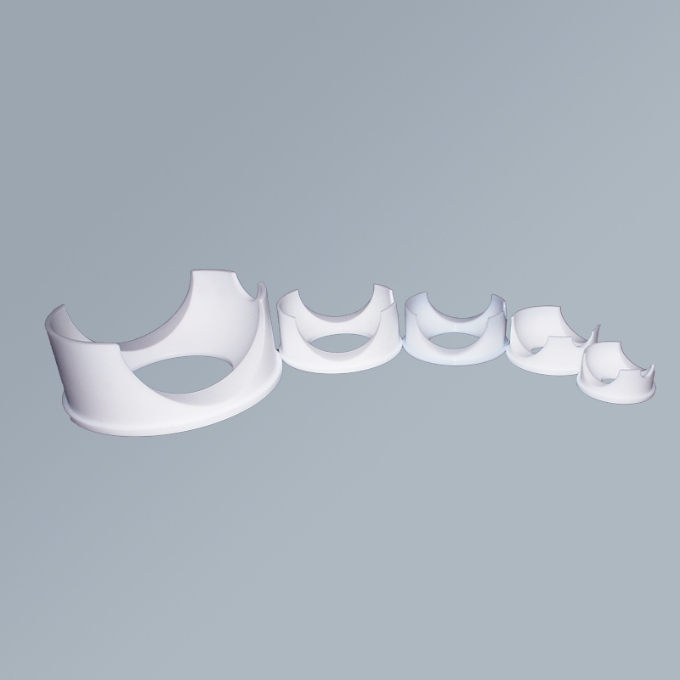

PTFE valve seat product details:

1.material properties:

Excellent corrosion resistance: PTFE valve seats are resistant to almost all chemicals, including strong acids, strong bases and most organic solvents, which makes them stable in a variety of corrosive environments.

Good sealing: PTFE material has excellent self-lubrication and low coefficient of friction, which makes the valve seat can easily fit with the valve flap or ball when it is closed, forming a tight seal and effectively preventing media leakage.

Excellent working temperature range: PTFE valve seats can work normally in a wide range of temperatures and can usually withstand extreme temperature changes from low to high temperatures.

2.Structural design:

HIGH PRECISION MACHINING: PTFE valve seats are usually machined through precision machining to ensure the accuracy of their shape and size. This helps the tight fit between the seat and the valve flap or ball and improves the sealing effect.

Sealing surface optimization: The sealing surface design of the seat is optimized to minimize the potential for leakage. Some designs also add special coatings or treatments to the sealing surfaces to enhance their wear and corrosion resistance.

|

|

|

|

|

|

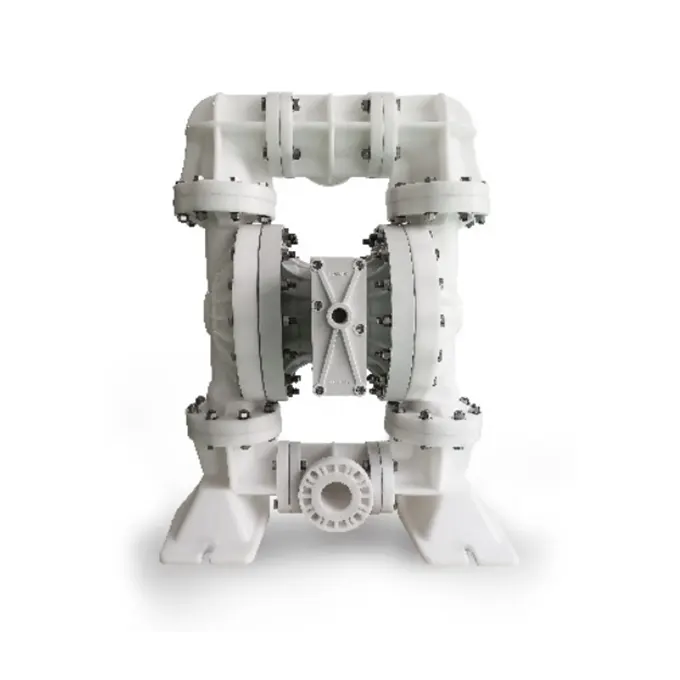

Applications

PTFE valve seats are suitable for many types of valves, such as ball valves, globe valves, etc. They are widely used in many industries, such as chemical, pharmaceutical, food, petroleum, natural gas, etc., to meet the needs of different media and working environments

Chemical industry: PTFE valve seats are widely used in the chemical industry to handle various corrosive media and ensure the safe operation of pipelines and equipment.

Pharmaceutical industry: In pharmaceutical production, PTFE valve seats are used for sealing pharmaceutical equipment and pipelines due to their non-toxic and corrosion-resistant properties.

Food industry: food production needs to ensure the purity of the medium and hygiene, PTFE valve seat because of its good corrosion resistance and hygienic properties and is widely used.

| Properties | Unit | Idicator |

| Tensile Strength | Mpa | 》15 |

| Elongation at Break | % | 》150 |

| Apparent Density | g/cm² | 2.1-2.3 |