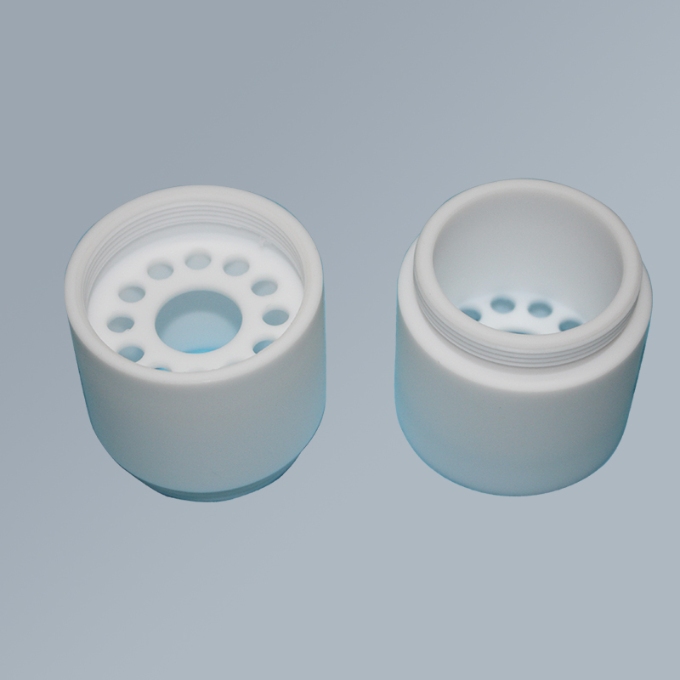

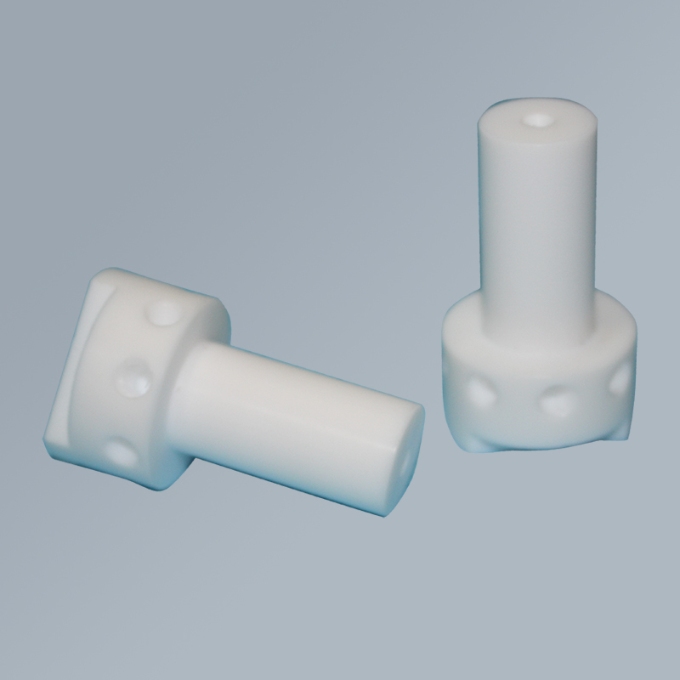

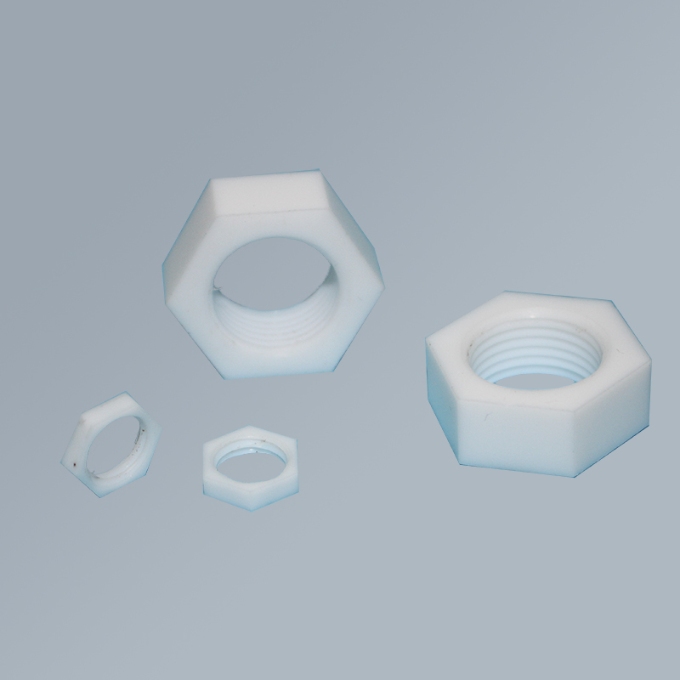

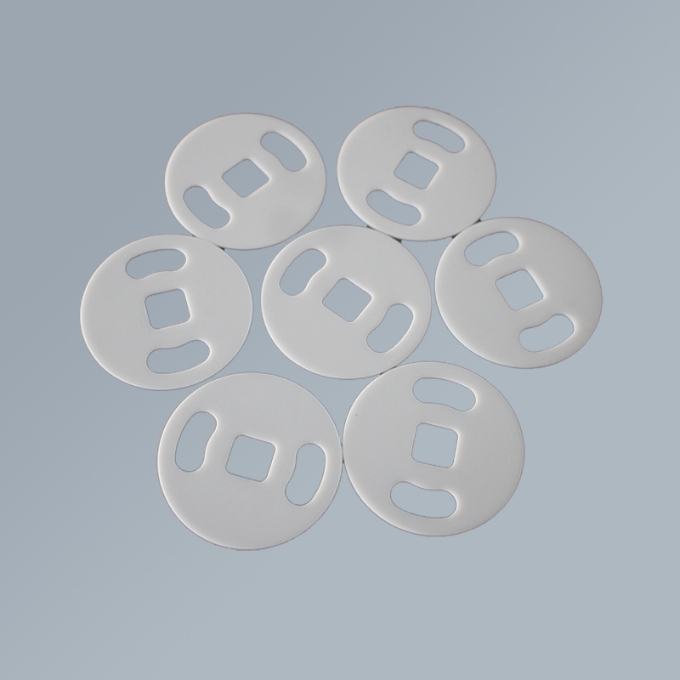

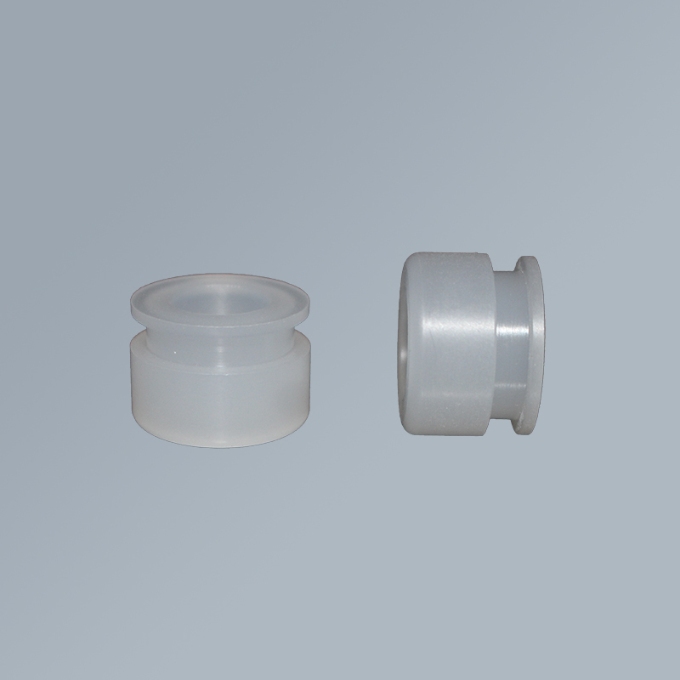

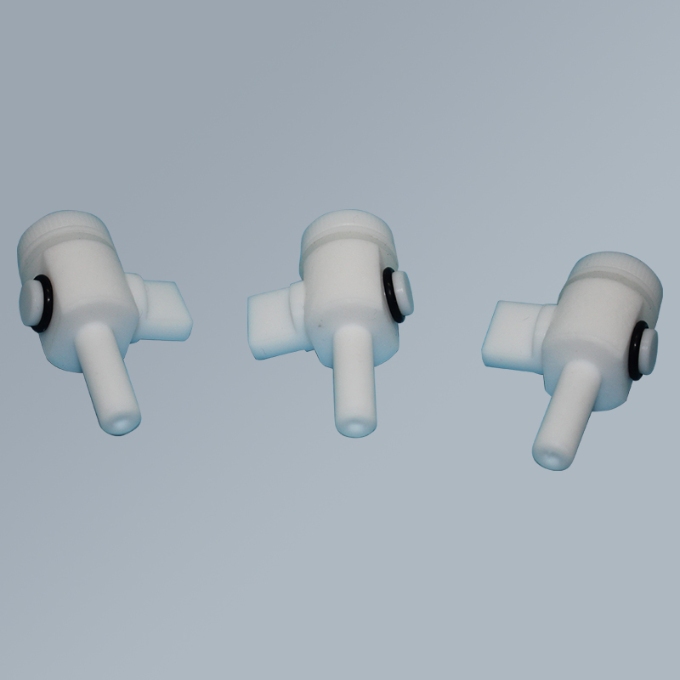

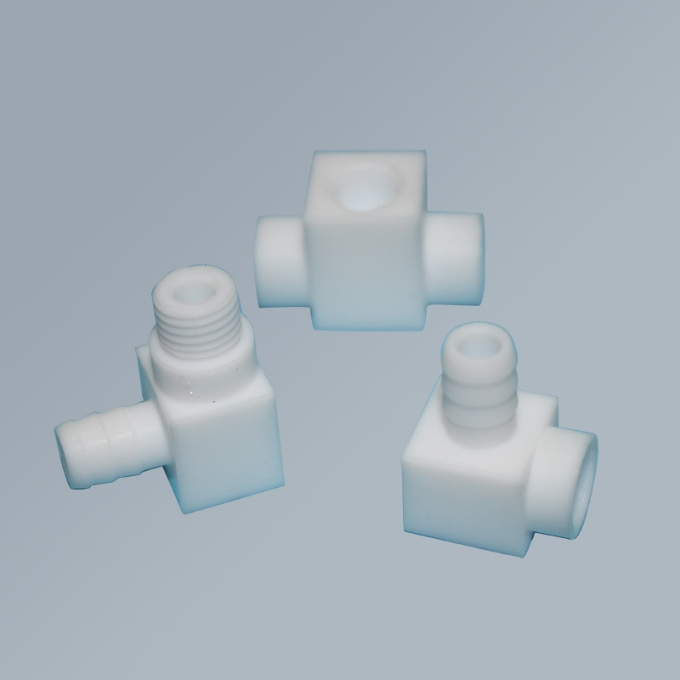

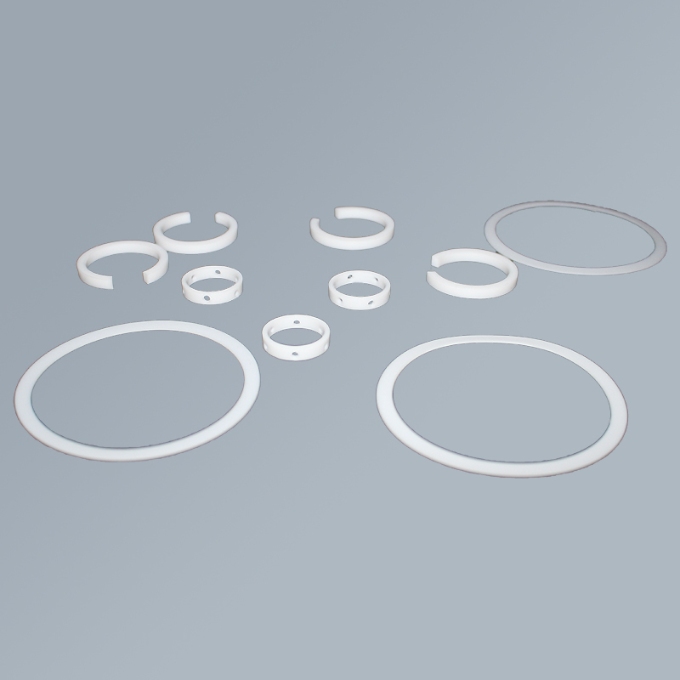

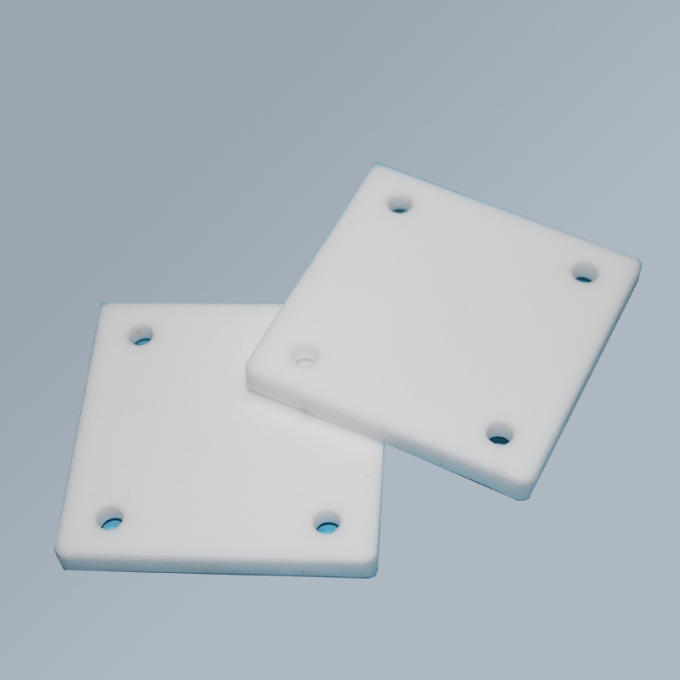

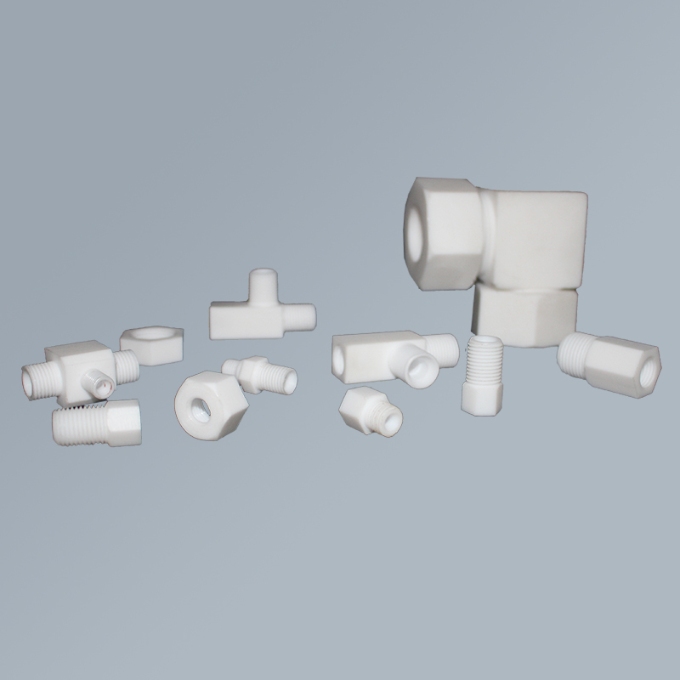

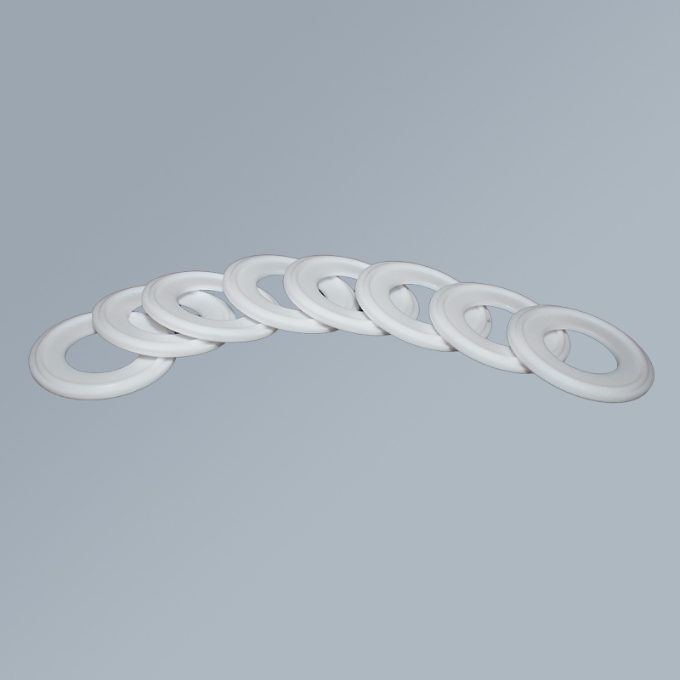

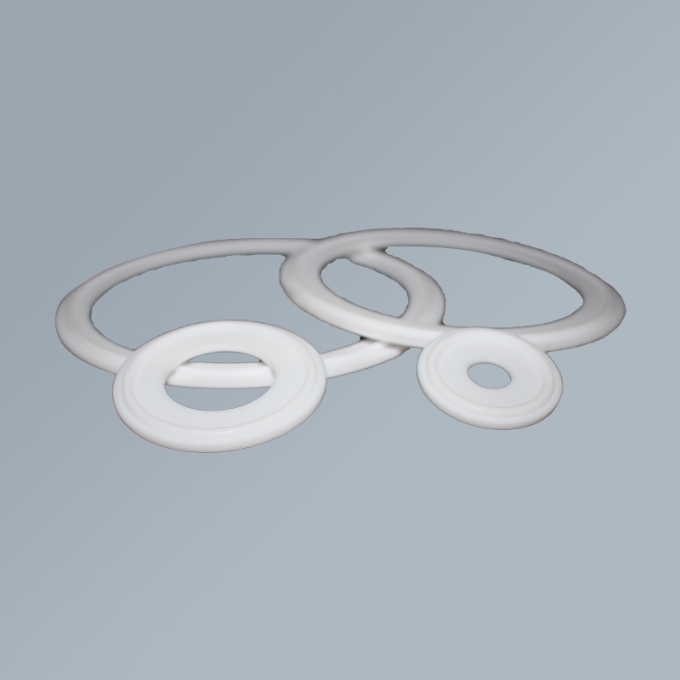

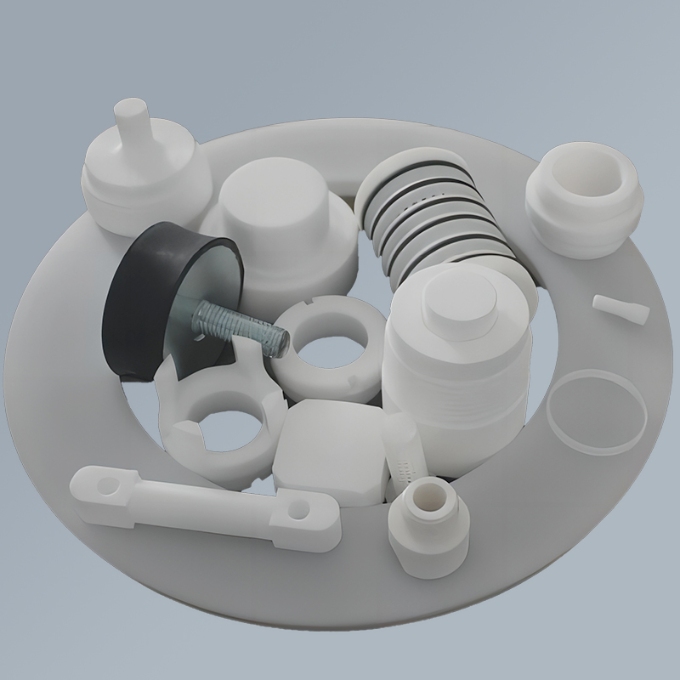

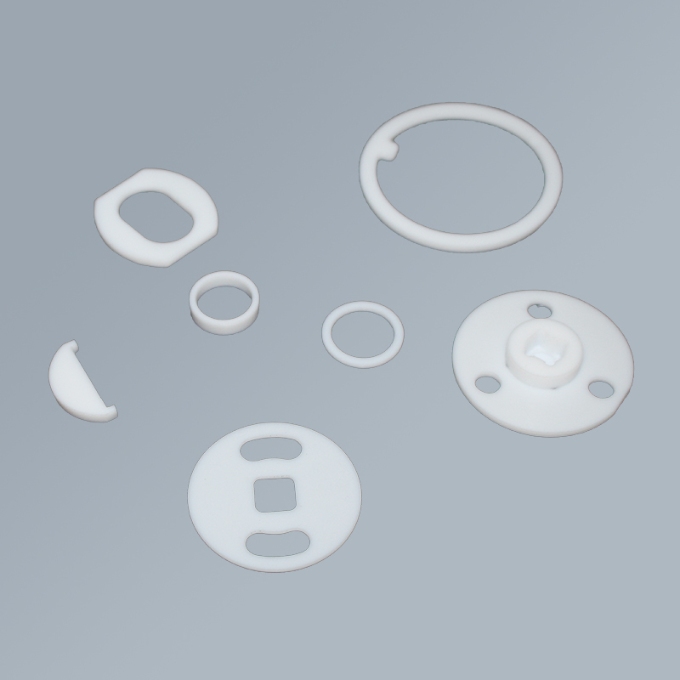

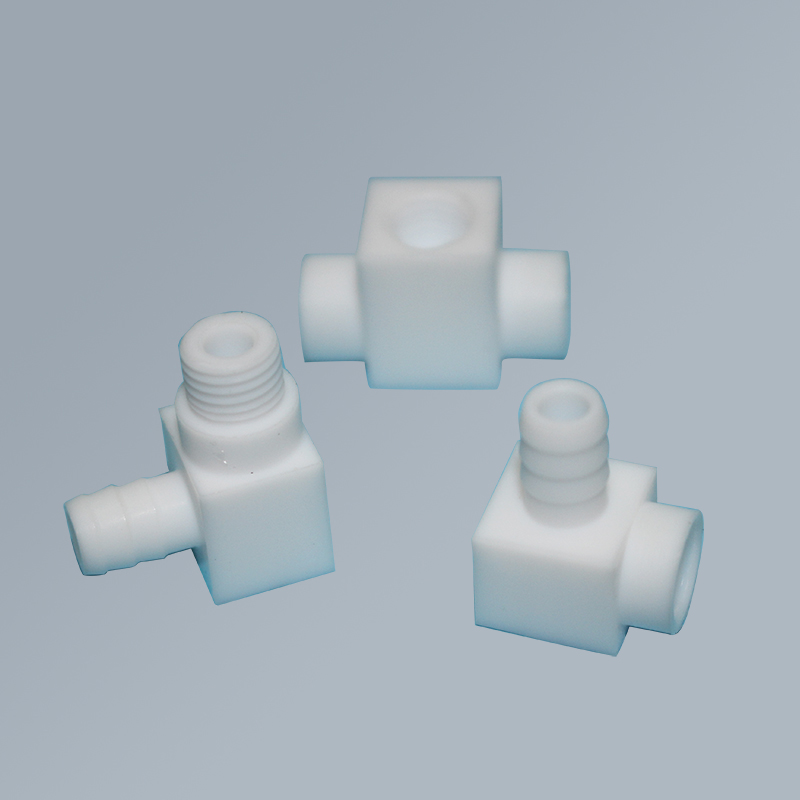

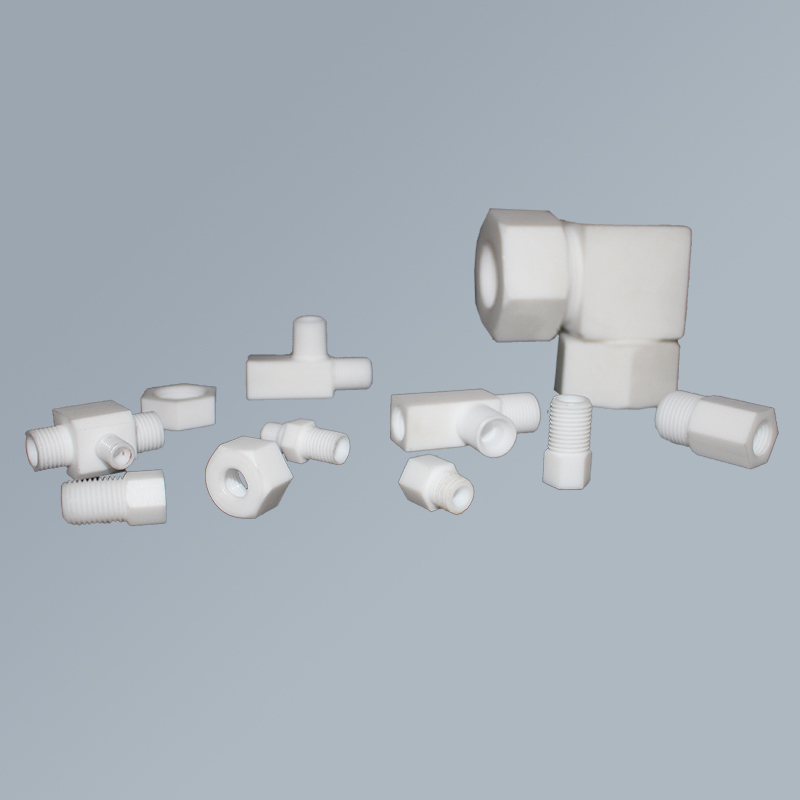

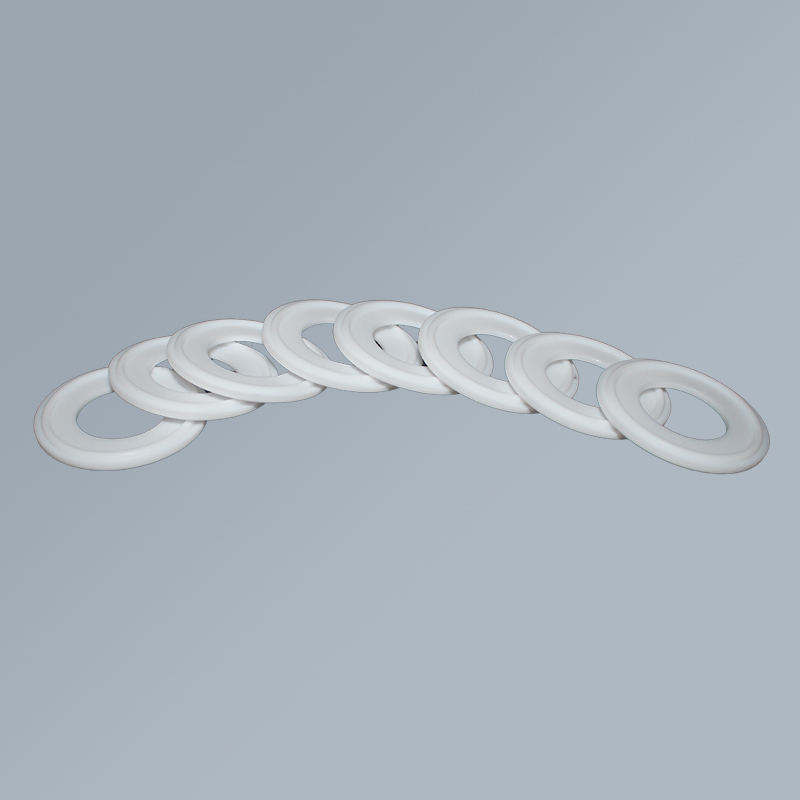

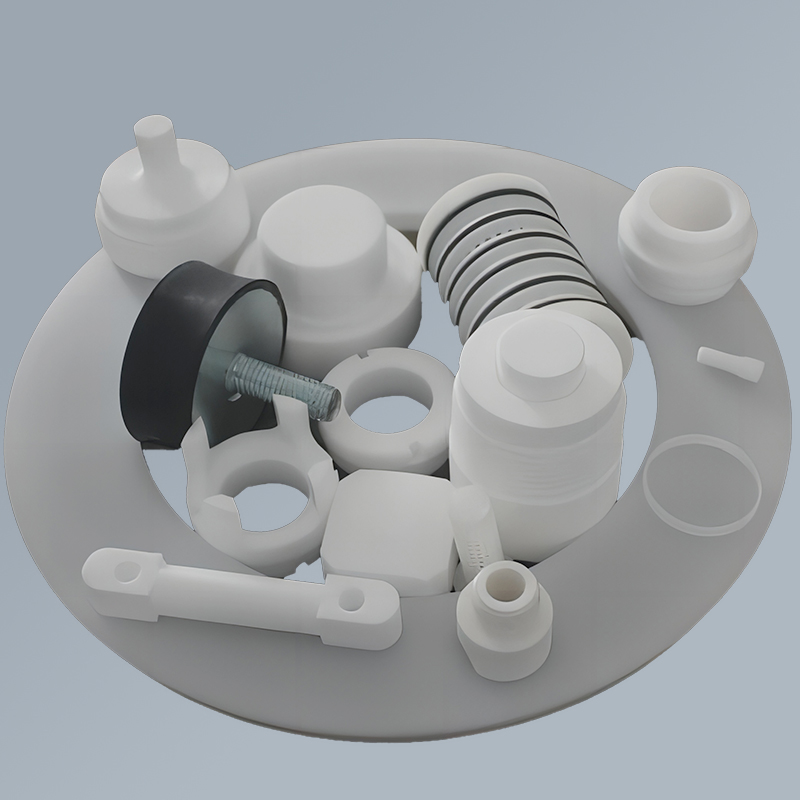

PTFE Shaped Parts

- excellent chemical stability

The company's products and services have been widely recognized by the industry as being of high quality, and the company's products and services have been widely recognized by the industry as being of high quality, and the company's products and services have been highly valued by the industry. This characteristic makes it work stably for a long time in the corrosive environment in chemical industry, pharmaceutical and environmental protection field.

- Excellent high and low temperature resistance

PTFE profiles can maintain stable working performance in a wide range of temperatures, its working temperature range from -200 ℃ to +260 ℃. Whether in the cold freezing environment or in the high temperature heating process, PTFE profiles can maintain its original physical and chemical properties, without deformation or damage.

- Low coefficient of friction and good self-lubricating properties

PTFE profiles have a very low coefficient of friction and a very smooth surface that does not easily adhere to other substances. This makes it excellent in dynamic friction applications, reducing wear and heat generated by friction and improving equipment life and efficiency.

- Excellent electrical properties

PTFE profiles have extremely high insulation resistance and breakdown voltage, making them ideal for use in electrical and electronic applications. It can be used to manufacture high-voltage insulating parts, cable insulation, etc., to ensure the safe and reliable operation of electrical equipment.

- Good processing performance

PTFE shaped parts can be precisely processed and customized according to customers' needs, including shape, size, thickness and surface treatment. Its easy processing characteristics make the production process less loss, improve production efficiency and product quality.

- Flexible customization options

PTFE profiles can be customized according to different application scenarios and needs, including color, marking, precision and tolerance control. This flexibility enables PTFE profiles to meet a variety of complex and special needs and adapt to the trends of different industries.

|

|

|

|

|

|

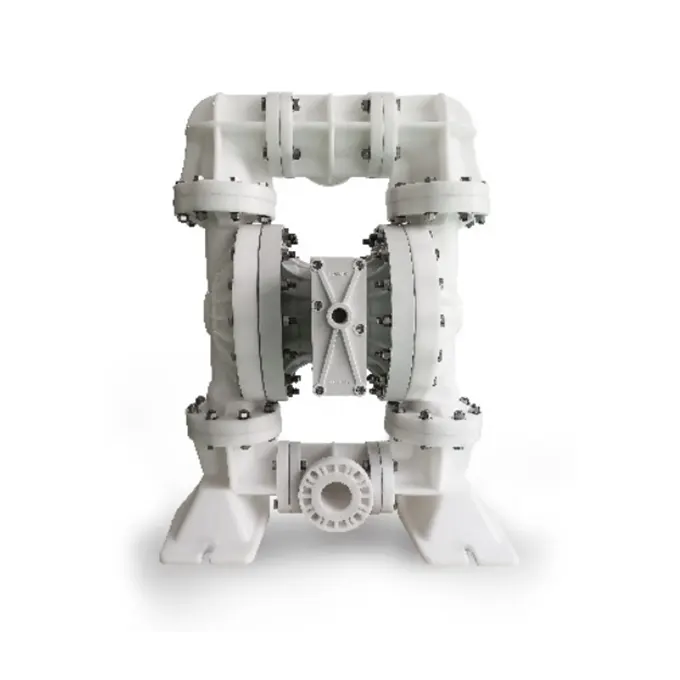

Areas of application*

Because PTFE profiles have so many excellent properties, they are widely used in a variety of fields such as chemical, machinery, bridges, electric power, aviation, and electronics. In these fields, PTFE profiles can solve many complex problems, such as expansion and contraction due to thermal expansion and vibration, sliding parts in poorly lubricated environments, and in environments requiring high corrosion resistance.

| Properties | Unit | Idicator |

| Tensile Strength | Mpa | 》15 |

| Elongation at Break | % | 》150 |

| Apparent Density | g/cm² | 2.1-2.3 |